The pharmaceutical industry places an immense emphasis on product quality, safety, and compliance with regulatory standards. Within this context, capsule manufacturing plays a pivotal role, as capsules are a common dosage form for a wide range of medications. Ensuring the quality of these capsules is paramount, and one of the critical technologies employed to achieve this is Vision Inspection Systems. In this technical article, we will explore the significance of Vision Inspection Systems in capsule manufacturing and how they contribute to quality assurance and efficiency in the production line.

The Role of Vision Inspection Systems

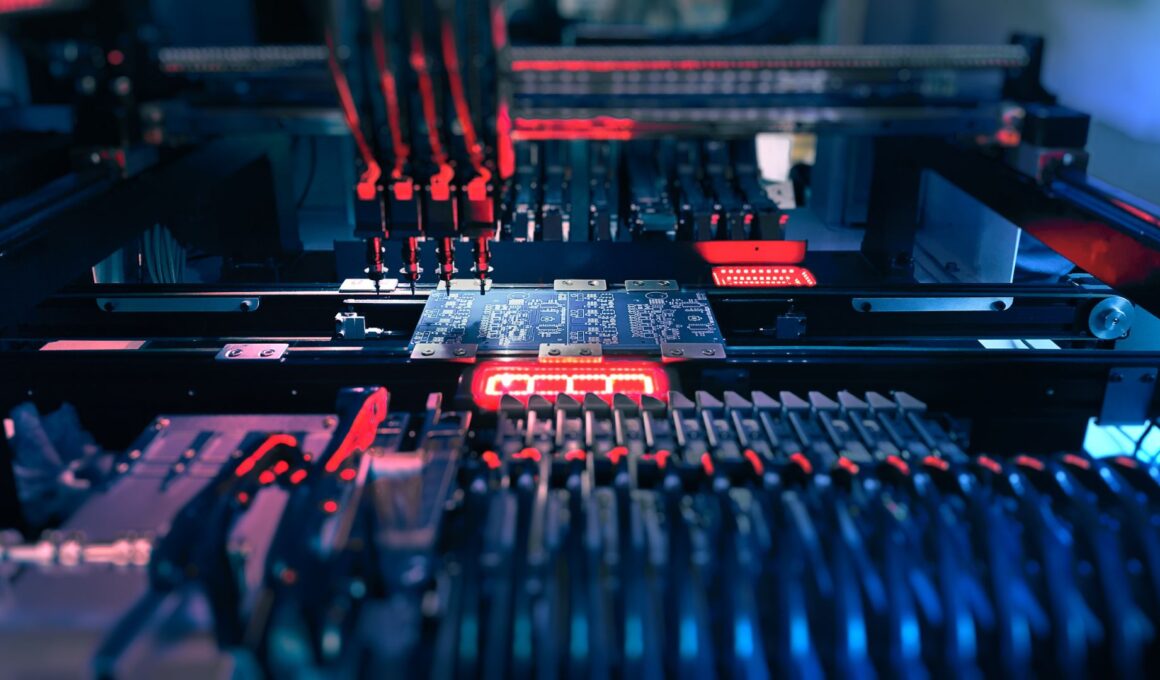

Vision Inspection Systems are advanced technologies designed to perform automated visual inspections of capsules along the manufacturing line. These systems employ high-resolution cameras, sophisticated software, and machine learning algorithms to detect, analyze, and categorize various defects or irregularities in capsules. The primary objectives of Vision Inspection Systems in capsule manufacturing include:

1. Capsule Integrity Verification:

- Ensure the capsules are intact with no cracks, splits, or deformities that could compromise the product’s integrity and safety.

2. Fill Level Inspection:

- Verify that capsules are uniformly filled with the correct dosage of the active pharmaceutical ingredient (API) or formulation.

3. Identification of Foreign Particles:

- Detect and reject capsules containing foreign particles, such as contaminants or extraneous materials.

4. Color and Print Inspection:

- Confirm that capsules have the correct color, branding, and labeling as per product specifications.

5. Size and Shape Consistency:

- Ensure that capsules conform to the prescribed size and shape standards, preventing variations that could affect dosing accuracy.

Advantages of Vision Inspection Systems

The implementation of Vision Inspection Systems in capsule manufacturing offers several significant advantages:

1. Enhanced Product Quality:

- By consistently identifying and rejecting defective capsules, Vision Inspection Systems ensure that only high-quality capsules reach the market.

2. Compliance with Regulatory Standards:

- Vision inspection helps pharmaceutical companies adhere to stringent regulatory requirements by minimizing the risk of product recalls and non-compliance issues.

3. Increased Efficiency:

- Automation reduces the need for manual inspections, thereby increasing production line efficiency and reducing labor costs.

4. Real-time Data and Traceability:

- Vision Inspection Systems provide real-time data on the production process, allowing for immediate corrective actions and traceability.

5. Minimized Waste:

- Defective capsules are identified and removed early in the manufacturing process, reducing material waste and associated costs.

Key Considerations in Implementing Vision Inspection Systems

To maximize the benefits of Vision Inspection Systems in capsule manufacturing, companies should consider the following:

1. System Integration:

- Ensure seamless integration of the Vision Inspection System with the capsule manufacturing line, including synchronization with other equipment.

2. Validation and Calibration:

- Thoroughly validate and calibrate the system to ensure accurate and consistent results.

3. Training and Maintenance:

- Train operators and maintenance personnel on system operation and routine maintenance procedures.

4. Flexibility and Adaptability:

- Select a system that can adapt to changes in capsule specifications and production requirements.

5. Data Management:

- Implement robust data management and analysis tools to track and analyze inspection data for continuous process improvement.

Conclusion

Vision Inspection Systems have become indispensable in capsule manufacturing, contributing significantly to product quality, safety, and regulatory compliance. Their ability to perform high-speed, accurate, and automated inspections ensures that only defect-free capsules reach consumers, enhancing pharmaceutical companies’ reputation and bottom line. As the pharmaceutical industry continues to evolve, the integration of advanced technologies like Vision Inspection Systems is key to meeting the industry’s stringent quality standards while maintaining operational efficiency.