The packaging industry is a dynamic and ever-evolving sector, driven by changing consumer demands, environmental concerns, and the need for efficiency. One of the key innovations shaping the packaging landscape is multi-format packaging, and at the heart of this innovation are Form-Fill-Seal Horizontal Machines. In this technology-focused article, we will delve into the world of multi-format packaging and how Form-Fill-Seal Horizontal Machines are streamlining flexibility in packaging.

The Rise of Multi-Format Packaging

Multi-format packaging is a response to the growing need for flexibility in the packaging industry. Consumers today expect a wide range of product sizes, formats, and packaging materials. Meeting these demands requires packaging solutions that can adapt quickly without compromising efficiency or product quality. Multi-format packaging addresses these challenges, offering the ability to switch between various formats seamlessly.

The Role of Form-Fill-Seal Horizontal Machines

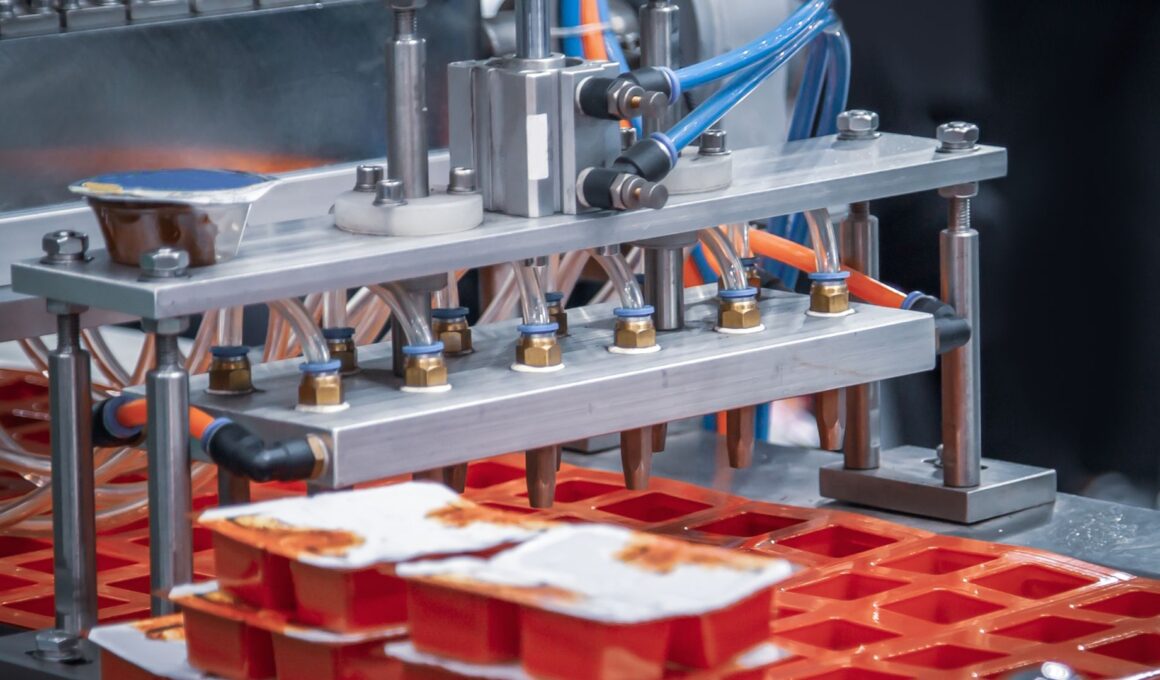

Form-Fill-Seal (FFS) Horizontal Machines are instrumental in achieving multi-format packaging capabilities. These machines are designed to create, fill, and seal packages horizontally, offering several advantages:

1. Flexibility in Packaging Formats:

- FFS Horizontal Machines can handle a wide range of packaging formats, including pouches, sachets, bags, and more. This versatility allows manufacturers to switch between formats with ease.

2. Quick Changeover:

- Quick changeover capabilities minimize downtime during format transitions. Tool-less adjustments and intuitive interfaces simplify the changeover process, making it efficient and cost-effective.

3. Reduced Material Waste:

- These machines are optimized to minimize material waste. Precise filling and sealing processes reduce product and packaging material losses, contributing to sustainability goals.

4. Customization and Branding:

- FFS Horizontal Machines enable customization of packaging through options like variable data printing and easy integration of branding elements. This flexibility caters to unique product requirements and branding strategies.

5. Integration with Sustainability Initiatives:

- Multi-format packaging with FFS Horizontal Machines aligns with sustainability goals. It allows manufacturers to choose eco-friendly packaging materials and optimize material usage, reducing the environmental impact.

6. Consistency and Quality:

- These machines ensure consistent filling and sealing, resulting in high-quality packages that meet stringent quality standards.

7. Efficiency and Speed:

- FFS Horizontal Machines are designed for high-speed packaging, improving overall production efficiency and throughput.

Applications Across Industries

The versatility of FFS Horizontal Machines makes them invaluable across various industries:

- Food and Beverage: Multi-format packaging caters to diverse food products, including snacks, condiments, and ready-to-eat meals.

- Pharmaceuticals: These machines meet the demands for different dosage forms and package sizes in the pharmaceutical industry.

- Cosmetics and Personal Care: FFS Horizontal Machines enable customization of packaging for cosmetics, lotions, and toiletries.

- Household Products: Versatile packaging solutions accommodate various household products, from cleaning agents to pet food.

Multi-format packaging, powered by Form-Fill-Seal Horizontal Machines, is redefining flexibility and efficiency in the packaging industry. Manufacturers can adapt to changing market demands, reduce material waste, and enhance product quality while meeting sustainability objectives. As consumer preferences continue to evolve, multi-format packaging with FFS Horizontal Machines ensures that brands can stay agile and responsive in a rapidly changing market. This innovation is not just about packaging; it’s about delivering products to consumers in the most efficient, sustainable, and flexible way possible.